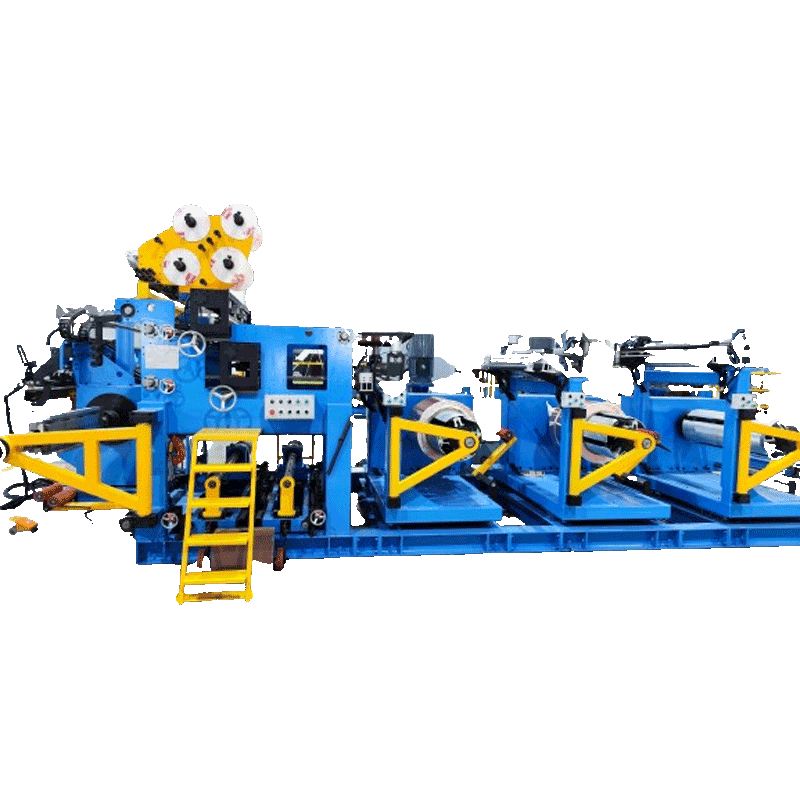

LV foil coil e sebelisa botenya bo fapaneng ba koporo kapa foil ea aluminium joalo ka mokhanni, lisebelisoa tsa mofuta o pharaletseng oa li-band e le insulation ea lera, matsoelintsoeke a felletseng mochining o fepelang oa mofuta oa foil, ho etsa coil.

Thepa ena e ka boela ea sebelisoa ho li-coil windings tse tšoanang tsa indasteri ea motlakase.

Mochine o sebelisa mokhoa oa ho laola PLC o nang le litšobotsi tsa boemo bo phahameng ba ho iketsetsa.

Ⅱ.Sebopeho le Mosebetsi oa Thepa

BR/III-1100 Three-Layer Foil Winding Machine kenyeletsa

1) Sesebelisoa sa foil de-coiling 2) Sesebelisoa sa moea 3) Sesebelisoa sa ho senya lera

4) Likarolo tse ka sehloohong tsa foreimi 5) Sesebelisoa sa Welding 6) Ho senya le ho hloekisa sesebelisoa

7) Sesebelisoa sa ho itšeha 8) Sesebelisoa sa ho koala sekheo sa ho qetela joalo-joalo

III. Mekhahlelo ea mantlha ea tekheniki

| Sr# | ITEM | TS'ELISO |

| 1 | Koele | Sebaka sa tšebetso |

| 1.1 | Bolelele ba axial | 250 ~ 1100 limilimithara |

| 1.2 | Axial length (kenyelletsa lead) | 400~1760 limilimithara (ka lead RH 16 inch, LH 10inch) |

| 1.3 | Bophara ba ka ntle (Boholo) | Φ1000 |

| 1.4 | Sebopeho sa coil | Boima ba ho pota-pota / cylindrical / rectangular / coil ≤2000KG |

| 1.5 | Bophahamo ba bohareng | 850 limilimithara |

| 2 | Lisebelisoa tsa Coil | Foil ea koporo, foil ea aluminium |

| 2.1 | Bophara | 250-1100 limilimithara |

| 2.2 | Botenya (Boholo) (Botenya bohle) | Foil ea koporo: 0.3-2.5mm Aluminium foil: 0.4-3mm |

| 2.3 | Coil bophara ba ka hare | Φ400-500mm |

| 2.4 | Bophara ba ka ntle ba khoele (Max) | φ1000mm |

| De-coiler | Lihlopha tse tharo tse ikemetseng |

| 3.1 | Bolelele ba ho beha cylinder | 1150 limilimithara |

| 3.2 | Katoloso ea mefuta e mengata ea cylinder e behang | Φ380~φ520 |

| 3.3 | Matla a ho beleha (Max) | 2000KG |

| 3.4 | Matla a ho atolosa (Motlakase) | 0~15000N Matla a katoloso a sa fetoheng |

| 3.5 | Mokhoa oa ho lokisa phoso | Bukana/Ka ho iketsa |

| Mochini o fefolang moea |

|

| 4.1 | Lebelo le tsoelipanang | 0 ~ 20 rpm |

| 4.2 | Torque e sebetsang (Max) | ≥ 8000N·M |

| 4.3 | Matla a phefolang | 20-30 KW |

| 4.4 | Tsela ea ho laola lebelo | Maqhubu a ho sokoloha stepless lebelo taolo |

| 4.5 | Moqomo wa mapheo | 50*90mm |

| 5 | Sesebelisoa sa welding |

|

| 5.1 | Mokhoa oa ho cheselletsa | TIG |

| 5.2 | Ho tsamaisa bar tjheseletsa botenya | ≤ 20mm |

| 5.3 | Lebelo la welding | Taolo ea lebelo la Auto-speed 0~1m /min Taolo ea lebelo e sa hataneng |

| 6 | Sesebelisoa sa ho khaola |

|

| 6.1 | Sebopeho sa ho itšeha | Lead Screw Cutting Disc |

| 6.2 | Ho poma lebelo | 1.5 m / mets |

| 6.3 | Ho khaola bolelele | 1150 limilimithara |

| 7. | Lera insulatingkokollasesebelisoa | |

| 7.1 | Layer insulation kentse shaft | 2 lihlopha |

| 7.2 | Lera insulation roll bophara ba ka ntle | ≤φ400 limilimithara |

| 7.3 | Layer insulation roll bophara ba ka hare | φ76 limilimithara |

| 7.4 | Lera insulation moqolo bophara | 250 ~ 1150 limilimithara |

| 7.5 | De-coil shaft tension mokhoa | Mofuta oa moea |

| 8. | TheQETAsesebelisoa sa ho koala sekoahelo |

|

| 8.1 | Bongata | Ka ho le letšehali le ka ho le letona ka 'ngoe lihlopha tse 4 |

| 8.2 | Qetellong insulation kantle bophara | ≤φ350 limilimithara |

| 8.3 | Qetellong insulation bophara bophara | Φ56 limilimithara |

| 8.4 | Bophara ba ho qetela ba insulation | 10-100 limilimithara |

| 9. | Rsesebelisoa sa ectifying (foil alignment) | Ie ikemetseng 3 lihlopha |

| 9.1 | Mokhoa oa ho lokisa | Sistimi ea motlakase ea lifoto |

| 9.2 | Ho lokisa ka nepo | Random±0 .4 limilimithara 20 lera khola ±1mm |

| 10. | Sistimi ea taolo ea motlakase | Mokhoa oa ho laola othomathike oa PLC |

| 10.1 | Palo ea li-digital | 4-digital (0–9999.9)) Ho bala ho nepahala 0.1 thinya |

| 10.2 | Khokahano ea ts'ebetso | Skrine sa ho thetsa ka mebala |

| 11. | Tse ding |

|

| 11.1 | Sesebelisoa sa ho itšeha ka lera | Configuration lihlopha tse peli |

| 11.2 | Foil thepa metshetshe deburring sesebediswa | Tlhophiso lihlopha tse tharo |

| 11.3 | Sesebelisoa sa ho hloekisa thepa ea foil | Tlhophiso lihlopha tse tharo |

| 11.4 | Tanka ea metsi a pholileng ea welding | tlhophiso |

| 11.5 | Phepelo ea motlakase | 3-PH,380V/50HZ (E ka etsoa ka mokhoa o ikhethileng) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com